|

Do you work with Inliners (Martin, Emba, Isowa, enz.) and are you looking for:

- Higher outputs

- Less machine stops

- More versatile adhesives for different board qualities

- More cost-efficient production

Then you should consider to have a look at our adhesives

Intercol has almost 40 years experience in industrial adhesives used in the corrugated board industry

1. Machines have to go faster and faster!

Because of changes in machinery, materials, markets and developing customer requirements factors as knowledge, innovation, the reliability and efficiency of your production become ever more crucial.

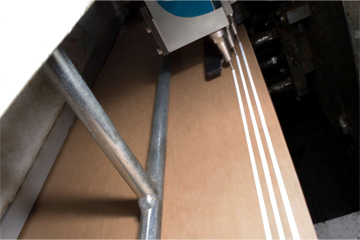

Machines have to run faster and more efficient to meet the production requirements nowadays. Therefore these machines need to be adapted, one of the big changes in inliner glueing machines is the change to non-contact glue application. Where previously a wheel or a contact-nozzle was used.

By introducing electronic control systems instead of mechanical triggering many advantages can be benefitted from, such as high speed glue application, more accurate and reliable adhesive patterns are saving money. It is therefore not surprising that adhesive-system suppliers respond to this development and appropriate solutions.

2. Adhesive Developments.

Non contact adhesive application systems have grown to complex integrated solutions in the corrugated board industries. These systems have created solutions for suppliers such as Bobst, Heidelberg, Vega and others to increase the production speed of their machines. Intercol has been involved in these developments from the beginning and has a broad sortiment of adhesives for non-contact glue application. Through collaboration with system suppliers, machine builders and the packaging industry itself, we are well acquanted with our customers needs. Therefore we can guarantee that our adhesives are developed to provide our customers with a reliable and succesfull production process.

3. Cost saving adhesives

An investment in new adhesive application equipment isn't cheap, but mostly this investment has a short payback time. Besides cost saving through higher machine speeds (probably combined with a faster drying adhesive) Cost savings are a result of:

- Less adhesive application, because the glue pattern can be interrupted.

- Better control and more consistent glue volume

- More control at higher and lower machine speeds. E.g. making glue-dots at low speed, and stripes at high machine-speed.

4. Adhesive requirements.

New dosing equipment needs new adhesives, with Intercol's adhesives you can benefit from:

- A minimal to no contamination of the nozzles showing so irregular glue patterns or nozzle blockages of the are avoided.

- Clean running, no spitting and/or "satelites"

- Good start/stop properties, even with more time consuming machine-stops

- No clogging of glue-filters

- Low time to fibre bond, enabling problem free packaging at the end of the line

- High tack adhesive, load on the glue lap does not led to fish-tailing or release.

5. Reliability

Due to increasing line speeds it's more and more usual to "protect" quality with electronic systems, such as capacitive or visual inspection for glue detection. Intercol is familiar with several detection techniques to ensure smoot cooperation between glue and the electronic detection system. Besides UV-colour we have other visual possibilities, to build into our adhesive formulations Due to increasing line speeds it's more and more usual to "protect" quality with electronic systems, such as capacitive or visual inspection for glue detection. Intercol is familiar with several detection techniques to ensure smoot cooperation between glue and the electronic detection system. Besides UV-colour we have other visual possibilities, to build into our adhesive formulations

6. Right raw materials

Many packaging materials have find their destination in food industries. In these market are HACCP and food related laws strictly necessary. Adhesives need to meet several requirements as well, such as EU-LAW, FDA, BfR, SML, REACH, etc.. Raw materials are preferably selected to meet all these requirements. Many packaging materials have find their destination in food industries. In these market are HACCP and food related laws strictly necessary. Adhesives need to meet several requirements as well, such as EU-LAW, FDA, BfR, SML, REACH, etc.. Raw materials are preferably selected to meet all these requirements.

More and more Phthalates were were seen as suspicious plasticizers. Already since 2010 Intercol replaced this plasticizer with food-approved plasticizers, to avoid any discussions on this topic, in line with our environmental goals.

Above mentioned specifications, do result in an interesting range of adhesives, specialized for applications in producing corrugated board products.

Are you looking for a standard adhesive solution, do you wish a taylor made solution, or do you have any questions please contact:

Mr. Adrie Donker

Adhesive- and application specialist, Intercol BV

Mobile: +31-6-20015042

Office: +31-318-636363

Fax: +31-318 639474

Mail:

This e-mail address is being protected from spambots. You need JavaScript enabled to view it

Web: www.intercol.nl |