|

A new benchmark in performance. It was a quiet revolution. But, a revolution, none the less. In 1998, Intercol launched the ground-breaking Futura range of hot melt adhesives has established a new benchmark for performance in countless packaging, labelling, woodworking and bookbinding industry applications. A new benchmark in performance. It was a quiet revolution. But, a revolution, none the less. In 1998, Intercol launched the ground-breaking Futura range of hot melt adhesives has established a new benchmark for performance in countless packaging, labelling, woodworking and bookbinding industry applications.

The range of Futura hot melt adhesives is stille extending, while new raw materials are available in an ongoing process.

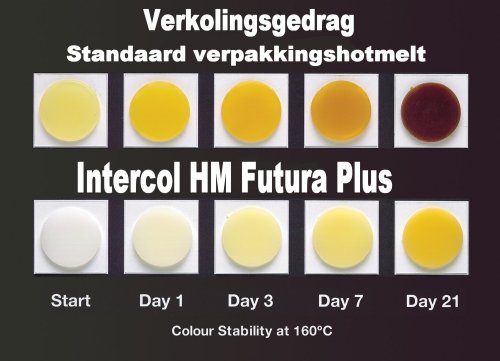

HM Futura adhesives do not char in the hot melt tank, are clean running and can be used across a wide range of production speeds. They also offer exceptional thermal stability. During seven day 160°C trials, viscosity changed by less than 1%. This unique characteristic eliminates the nozzle blockages associated with less advanced adhesives that can continually disrupt on-site production. In addition, unrivalled low temperature flexibility and heat resistance enable BAMFutura adhesives to be used with confidence in applications that may be exposed to temperatures ranging from -50°C to +100°C.

Proven solutions, value-adding benefits…

Hot melt Futura adhesives are inert, virtually odour-free and pearl white in colour, making them perfect for most packaging applications. Here, they provide strong and reliable adhesion without tainting foodstuffs, pharmaceuticals or other delicate products. Improved bonding to a wide range of materials, reduced inventory costs and competitive pricing are among a host of other value-adding benefits.

In addition, our hot melt adhesives expertise and commitment to research and development enable us to regularly enhance the Futura range in order to provide proven solutions to the ever-changing requirements of our customers. Our Futura Packaging, Futura Labelling, Futura Woodworking and Futura Bookbinding sections provide further information.

|